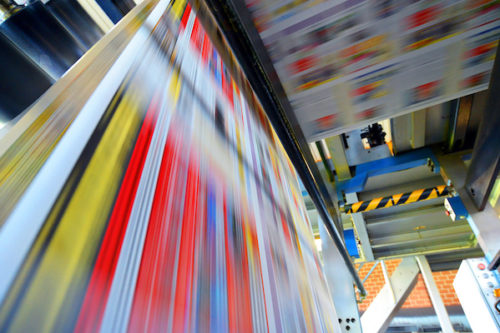

DBT Coatings, Inc. is an industry leader in the formulation and production of custom electron beam (EB) coatings and adhesives. We have extensive expertise developing EB-cured solutions that overcome process challenges. Our advanced capabilities, such as our lab EB unit, and experience in diverse industries enables us to formulate solutions for a broad range of substrates and applications.

EB Products

EB solutions minimize irritating and malodorous components during the formulation stage, providing safer handling for operators and minimizing the risk of transferring odors or flavors to printed or packaged goods. EB solutions provide consistent cure and are free of initiators thereby reducing migration risks. As a result, EB products see broad usage in food packaging. EB-cured solutions offer a variety of benefits, including:

- Energy-efficient curing

- Instant cure and performance

- Low or no VOC content

- Compatibility with many substrate and application types

At DBT Coatings, we offer a variety of EB products that can be tailored to fit specific customer needs. Customizable factors include adjustable coefficient of friction (COF), gloss, adhesion properties, and more. We can also perform migration testing on your end products to ensure that the structure is fit for sensitive applications.

Our product portfolio includes EB varnishes, adhesives, and functional coatings:

Varnishes

Our EB varnishes are available with several standard and textured finish options.

- Gloss. Our EB gloss varnishes offer high-speed processing with excellent gloss, abrasion and chemical resistance, and adhesion properties.

- Matte. EB matte varnishes from DBT offer a smooth, high-clarity finish with low gloss values and abrasion and chemical resistance.

- Soft-touch. DBT’s EB soft touches provide exceptional haptic feedback and low gloss values. These products were formulated to be consumer-friendly and touchable.

- Grit. DBT’s EB grit series offers a selection of textures from subtle to rough.

Adhesives

DBT’s laminating adhesives are specially formulated for various film, carton, and label stock structures. Bonds can be tailored from destructive to release.

Functional Coatings

DBT has developed EB-cured functional coatings to improve the properties of substrates. We offer fully customizable functional coatings for:

- Shrink sleeve slip. DBT offers both matte and clear slip coatings for shrink sleeve applications.

- White inks. We offer true white inks in numerous opacities, as well as white adhesives for laminations.

EB Solutions Ordering Process

Our process begins by confirming the customer’s process requirements and performance expectations. If we don’t have a suitable off-the-shelf product to meet those needs, we will develop a tailored solution. If the product fails to perform to the customer’s expectations, we work closely with the client to identify the point of failure and retool the solution accordingly.

We custom-formulate our EB solutions to meet general market needs or specific customer application requirements. We minimize the use of irritating or malodorous components in our formulations, improving safety for users during handling and application.

When developing our products, we consider all aspects, including production, storage, transport, and end-use. With every formulation, we seek to minimize the customer’s need to trial multiple products and eliminate the experience of using a subpar product. We take every possible production to formulate the most robust solution possible, but sometimes it’s impossible to account for every variable. We keep an open line of communication with each customer and strive to provide the highest possible level of service, which helps us to identify as many production variables as possible and adjust formulations as needed.

EB Solutions at DBT Coatings

We offer lead times of 3-5 days on most orders, though research and development lead times for custom formulations may vary depending on the project details. We can accommodate a variety of product testing needs, including:

- California Prop 65

- GreenGuard

- Extractables/migration

- Other testing available upon request

We produce our UV solutions in a range of volume options to suit applications of varying sizes. Options include:

- Pail (40 lbs., 5 gallon container)

- Drum (450 lbs., 55 gallon container)

- Tote (2,200 lbs., 275 gallon container)

About DBT Coatings, Inc.

At DBT Coatings, Inc., our custom formulations set us apart from the competition because we don’t limit customers to off-the-shelf solutions. When you come to DBT for your EB solutions, you will receive a product backed by our state-of-the-art lab and our ability to manufacture fully customized products. If you try one of our products and it does not perform to your expectations, we will work with you to make adjustments until you’re completely satisfied with your order.

DBT also takes environmental sustainability very seriously. We develop formulations that are as eco-friendly as possible. All of our solutions feature low extraction, low-VOC/no VOC content, and low-waste production. Our energy-efficient EB solutions also use less energy to cure than other thermal curing systems.

To see how our EB solutions can benefit your application, please contact us today.