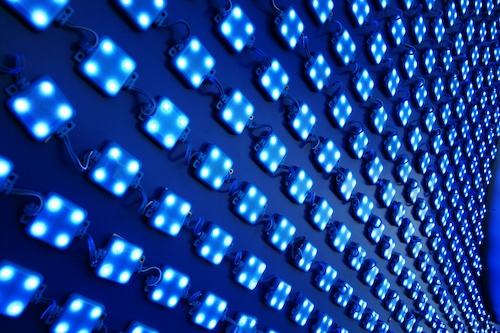

One of the major drawbacks of traditional ultraviolet (UV) curing systems is energy consumption and maintenance requirements. Traditional UV curing systems, like mercury (H) and doped bulbs (D or V), can’t be used on substrates with high heat sensitivity and require frequent bulb replacements along with other maintenance tasks that reduce productivity. Incorporating light-emitting diode (LED) technology into UV curing systems (UV-LED) eliminates all of these problems, allowing simplified and sustainable photopolymerization of energy-curable solutions.

One of the major drawbacks of traditional ultraviolet (UV) curing systems is energy consumption and maintenance requirements. Traditional UV curing systems, like mercury (H) and doped bulbs (D or V), can’t be used on substrates with high heat sensitivity and require frequent bulb replacements along with other maintenance tasks that reduce productivity. Incorporating light-emitting diode (LED) technology into UV curing systems (UV-LED) eliminates all of these problems, allowing simplified and sustainable photopolymerization of energy-curable solutions.

DBT Coatings is a premier manufacturer of eco-friendly, UV-LED-curable functional coatings, varnishes, adhesives, primers, and inks. We have extensive experience developing UV-LED solutions for an expansive array of substrates and use cases. Our in-house experts have formulated a variety of solutions for use with UV-LED curing systems.

LED Solutions

Compared to traditional UV curing systems, UV-LED solutions minimize odors and reduce irritants produced during the curing process to provide a safer work environment for technicians. With significantly lower power usage and less use of consumables, these systems provide an ideal solution for users looking to implement more eco-friendly solutions into their production operations. UV-LED solutions also provide an ideal method for coating and curing heat-sensitive substrates that would melt under conventional curing lights.

Of note, the chemistry requirements for UV-LED-cured solutions differ slightly between the requirements of traditional UV solutions. DBT Coatings helps our customers reformulate their usual functional coatings, varnishes, adhesives, primers, or inks so they can take advantage of the benefits provided by UV-LED curing technologies without sacrificing performance.

We can tailor any of our products to meet specific customer needs, including adjustments to performance, COF, cure rate, gloss, and more. We also conduct migration testing on customer products to make sure that the structure meets regulatory criteria or application specifications. Our current UV-LED solutions break down into multiple categories: functional coatings, varnishes, adhesives, primers, or inks.

Functional Coatings

The experts at DBT have developed UV-LED-cured coatings and resins to improve functionality and optimize performance. We offer functional coatings for:

- Shrink sleeve slip. DBT offers both matte and clear slip coatings for shrink sleeve applications.

- White inks. We offer true white inks in numerous opacities, as well as white adhesives for laminations.

- Weatherability/outdoor protection. DBT has developed proprietary low-yellowing and ink protection chemistries for outdoor applications.

- Solutions vary from concrete tape protection and fiber-reinforced composites. Please contact us with your requirements.

Varnishes

We offer standard UV-LED varnishes in gloss or matte varieties:

- Gloss. Our UV gloss varnishes facilitate high-speed processing, offering features including high gloss, excellent adhesion, and good chemical resistance.

- Matte. DBT’s UV matte varnishes impart a smooth and clear finish with low gloss value.

DBT also offers low migration varnishes for sensitive applications:

- Low Migration Series. We offer varnishes formulated with alternative chemistries for applications where extraction or migration potential are of concern.

Adhesives

DBT Coatings offers UV-LED adhesives for packaging applications, such as films, cartons, and labels.

- Lamination. DBT specially formulates our laminating adhesives for use with various carton, film, and label stock structures. We can tailor the bond strengths, ranging from destructive to release.

- Pressure-sensitive adhesives (PSAs). Our PSAs facilitate high-speed processing and feature exceptional tack for films.

Primers

DBT Coatings offers UV-LED primers for packaging applications, such as films, cartons, and labels.

- UV inks. Our primers for inks grant the ability to print on difficult substrates. These primers also provide the flexibility to surface print instead of reverse printing.

- Laser printing/toner. Our laser printing primers facilitate laser printing on difficult substrates.

Inks

DBT Coatings offers UV-LED white inks for packaging applications, such as films, cartons, and labels.

- White ink. Our white ink provides high opacity while minimizing yellowing and potential migration.

Ordering Process

We work closely with each customer to determine their exact process requirements and performance expectation. Before recommending an off-the-shelf product, we evaluate the customer’s requirements and determine a solution for their needs. If the product fails to perform as expected, we will work closely with the customer to identify the reason for failure and adjust the formulation accordingly.

DBT Coatings’ experts thoughtfully develop every product in our line-up to handle uses ranging from production through end-use. We engage in active communication and focus on providing superior service to every customer. Our approach ensures our customers don’t need to conduct trials with too many products or overcome challenges associated with using subpar products.

LED Solutions at DBT Coatings

We sell our products in the following volumes:

- Pail (40 lbs., 5-gallon container)

- Drum (450 lbs., 55-gallon container)

- Tote (2,200 lbs., 275-gallon container)

DBT manufacturers most solutions in 3-5 days, though our research and development periods may vary depending on the exact project specifications. Our capabilities expand well beyond our off-the-shelf solutions, and our lab technicians have significant experience with troubleshooting problems and identifying solutions for our customers.

When buying from DBT, our customers can expect to receive the same exact product every time, whether they’ve purchased five gallons or 40,000 gallons. In the event that we need to adjust a formula due to discontinued materials or supply chain shortages, we will always notify the customer in advance to avoid surprises.

DBT Coatings tests and evaluates all products throughout development. For more information on our testing practices or capabilities, please view our analytical page. Our customers can rest assured that we have used all available tools to guarantee that each lot has been manufactured to specifications.

About DBT Coatings

We specialize in formulating solutions that meet the exact needs of our customers and offer a full product line of radiation-curable varnishes and adhesives. When partnering with DBT, our customers benefit from our state-of-the-art lab and extensive sustainable manufacturing capabilities. We will always work closely with the customer to provide them with a solution that performs exactly as necessary.

To see how DBT Coatings can support your operation with UV-LED solutions, please contact us or request a quote today.